Story from Millenium Technologies – LINK HERE

The most common mode of failure for 2-stroke engines is detonation. We asked 3 time AMA pro mechanic of the year, multiple SX/MX championship winning crew chief, and Millennium Technologies Technical Manager, Tom Morgan to put together brief guide on two stroke detonation and how to prevent it. We hope its helpful.

Fuel octane or compression induced detonation

This picture illustrates the most common form of two stroke detonation. It appears as a pitting around the perimeter of the bore on the side opposite the exhaust. The edge of the piston and the OD of the squish area will exhibit damage. More severe detonation will look like the cylinder and head in these pictures.

Slight detonation shows up as a small roughing of the area, appearing much like it has been lightly sand blasted.

There may also be scoring down the side of the piston due to molten piston material being splattered onto the bore and disrupting the lubricating film of oil.

There are two ways to prevent this type of detonation from occurring:

1. Run a better fuel (higher octane)

2. Lower the compression ratio.

This type of detonation can happen even if your engine is all stock. Modern pump gas is engineered for automobile use, not for two strokes. It is low lead and high ethanol…..the opposite of what a high performance two stroke engine requires. There are some stock engines which are prone to this type of detonation; the engine designer pushed the tuning level of the engine too close to the edge. With the decline of pump gas quality, reliability is now questionable. If you see this condition in your stock engine you must consider using a higher octane fuel or having the head machined to lower the compression ratio slightly.

Lean fuel mixture induced detonation

Detonation from a lean air/fuel ratio appears on the exhaust port side of the piston. This type of detonation is usually more severe than octane detonation, causing more damage and a quicker engine failure. The piston crown will exhibit damage in the exhaust port area, in severe cases the edge of the piston above the ring will disintegrate. Damage to the ring will occur and the exhaust side of the piston will be scuffed and damaged.

In cases where the mixture is slightly lean or occasionally lean under certain conditions the evidence of detonation will be more subtle. The ring will overheat. This will be evident as a slight blue color on the exhaust side of the ring, a slight flat spot on the ring where it contacts an exhaust bridge, or a broken ring.

How do I know if my engine is detonating before damage occurs?

It is usually not possible to hear detonation until it is too late for your engine. Here are a few tips that may help you catch it before it is too late:

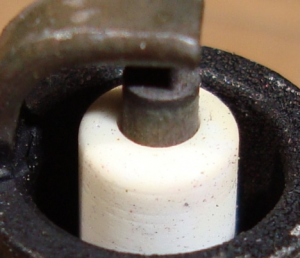

Look at your spark plug closely with a magnifying glass. Detonation (even slight) will show up as tiny speckles on the spark plug insulator (see picture). It appears like tiny metallic balls when magnified.

You should always carefully inspect your engine every time the head is removed. Look for the pitting or sand-blasted look around the perimeter of the piston crown and head squish band.

Tips to prevent detonation

Always make sure that your jetting (especially main jet) is rich enough. Jetting to the ragged edge of horsepower isn’t going to gain you much power overall. Jetting a size or two richer will not be noticeable on the track but your engine will be much more reliable.

Keep in mind that the correct jetting is dependent upon air density. Air density will change with:

Air temperature

Altitude

Barometric pressure

Humidity

Pay attention to changes in the weather and make jetting changes accordingly.

Jet more by “feel” more than plug color on a two stroke. Two strokes make the best power at low engine temperatures and that combined with oil in the fuel and cold heat range spark plugs makes for a good plug reading that is darker than most would expect to see. Your main jet should be rich enough that it is just a size or two below the sputter point at full throttle in the higher gears.

Don’t change fuels without confirming that your jetting is correct. This doesn’t apply so much to premium unleaded gas from your gas station (however winter and summer blends of fuel are different) This applies to different types of racing fuel or when switching from race fuel to pump fuel or vice versa.

Avoid the temptation to tweak the timing in search of power gains. Modern two strokes with digital ignitions are programmed to produce accurate timing according to RPM and some with throttle position also. This is the one aspect of the modern two stroke that is the most difficult and time consuming to improve upon. Small power gains from ignition timing usually produce a decrease in reliability unless thoroughly tested.

Leave A Comment