Class of 1950, Model 92

/wp-content/uploads/videos/Larry-Stroker-Williams1950-92.flv

This Larry “Stroker” Williams video was made possible by Paul Becker from the 1993 SAAB owners convention in Wisconson. It is the actual video from the SOC93. Larry can be heard talking about his windshield wiper he stole from his wife Kath’s kitchen squeegee. Larry is the passenger who gets out at the end of the video. There is also a “cameo appearance” by Eric Johnson. 😆

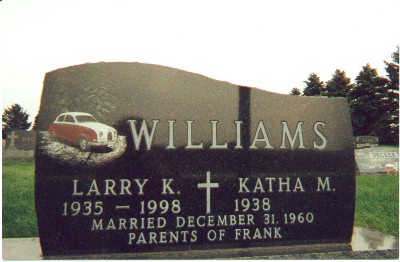

GOD BLESS YOU, LARRY – WE MISS YOU!!

When Larry passed away the SAAB community lost a dear FRIEND! The following newsletters were written in Larry’s memory or inspired by his SAAB spirit:

In March, 1998, Katha, Larry’s widow, sold me part of his collection of vintage SAABs. The “Old 92” was part of this collection. According to Larry, restoring the 92 was one of his most challenging projects. Following are three articles written by Larry describing the restoration.

And now the story of the 92 in Larry’s own words!!

February 95

The 92

During the National convention at Sturbridge, Mass, Ian and Pat let me know about a Model 92 in Michigan. So on the way home I stepped off the I-80 boulevard at Toledo and pointed Sadie north on 23. About ten minutes of this and my navigator remarked, “There must be an old SAAB in this direction!”

“Funny you should mention that! There may be a 92 in Flint!”

And there it was, not hid away in some cozy hay barn, but outside on soil fertilized by its own rust! Or maybe it was the falling paint flakes that hyped those weeds to grow right through the floor, the trunk, the engine bay, even the frame rails. Ah yes! Frame rails, I mused. If I had some frame rails I know I could come up with a floor pan to put between those frame calls. But alas, then I would also need wheel wells to attach those frame rails to!

[gallery_grid album=”Larry’s ’92” layout=”three_column” lightbox=”true”]

MY FIRST THOUGHTS WERE:

1. It looks like a spotted owl.

2. If this were a 96 I would junk it.

3. The engine is stuck.

4. Restoration would mean filing bankruptcy.

5. Katha is matching holes in car with holes in my head.

THEN MY 2ND THOUGHTS WERE:

lb. This endangered species needs protected.

2b. I could just keep it around for a conversation piece.

3b. Hey! It only has 2 pistons to get unstuck.

4b. I’ll sell the long nose cars and give up champagne.

5b. Katha already knows I’m crazy!

6b. One ride around the block and it’s worth it.

I HAD DEFTLY JUSTIFIED A SCORE OF 6 TO 5 IN MY FAVOR!

Negotiations for any car can be a lot of fun and in this case it took a standing offer in writing and a year of patience.

It was convention time the following year and I was packing Sadie for Seattle when Rob Collins of Trio Motors called and said, “Come and get your 92.” So I tossed 4 extra wheels in the 99 along with tools, tow bar and 1200 miles of white line fever for a round trip to Michigan.

I drove all night arriving as they opened. We took care of the paper work, I mounted the wheels, hooked up the tow bar, started for home, and broke a tow bracket at the first corner! The 92’s front wheels had just stayed straight ahead! So I substituted a couple of box end wrenches that reached back through the grill opening and made the bar real solid to the body. The front wheels were still dragging sideways on the turns (tires squealed a bunch), but it was safe so I hauled ass for home! The white line fever broke at 950 miles and I slept In Joliet.

With a new toy to play with, I didn’t really want to leave again. I got a little rotation on the 92 crank and saw that the cylinder walls were rusted upwards from where the twin pistons had evenly stopped. So I made a cocktail of half gas and half 2 stroke oil, pouring it in the spark plug holes and down the carb. I figured, while we toured out through the Great Northwest, fermentation would be working for me and free up all 764 of its CC’s! Not! When Sadie got us home, I put a wrench on that crank and all I got was that same little rotation!

Once a day for the next month I worked the crank back and forth a little, and fed her more of the cocktail. I even gave her a shot of Mystery Oil! (No luck). When I got close to a half turn of rotation it stuck again. It felt like the pistons were at the point of changing directions, so I said a little prayer to the god of 2 strokes and forced it over.

Now or never! I spun it a few times with the starter to blow the cocktail out of the crankcase. Put on a 96 expansion chamber (that hung out the grill), screwed in a pair of dry plugs, pulled the lever again and she started with a bang! Rattled me good! I stood there with the pipe blowing big time smoke into my socks. Katha came out to see what exploded! I just stood there and smiled. For a week!

Undated

The 92

I needed a clutch cable for the next step and made one from a 96 brake cable. The wing nut adjuster even fit. I also needed a 6 volt fuel pump and a fuel tank. The 12 volt Bendix pump off the Sonett II worked on 6 volts and a quart oil bottle strapped to the cowl became the fuel tank during that “One ride around the block!” I locked out the freewheel for the braking effect. I didn’t have title, plates, or insurance, so what did I need with brakes. It made sense at the time! The ride around the block was a smoky success.

At this point I needed to draw some firm guide lines for this project. Obviously a proper restoration was ruled out due to the poor condition of the body, parts availability, and shallow pockets of the present owner.

The start up phase was fun but the big question is where do I stop?

The answer came as a, what if. I thought what if the first owner had kept the car running for 45 years. How would that 92 look today? I’d say not pretty, modified as needed, and an “Old Fart” driving it. Hey!, I got all that covered. I started by taking measurements of the door openings and comparing them to Sadie before I cut out the remains of old floor, trunk, and frame rails. A SAAB package arrived from Steve Rossi with copies of the 92 parts book and service manual. I spent a week comparing the good book with the 92 and the long nose donor car. Excluding the torsion bars and transverse power train, it is amazing what will interchange with no modifying. Then again, some days I custom made everything!

With a unused rail for a pattern, a local sheet metal shop made left and right frame rails out of 16 gauge.

The gap, between the planks on my work bench, becomes a metal brake to form wheel wells or other panels. I still like to bolt all those pieces but I realized that I needed a welder to attach door posts to the rails.

It was time to go shopping for a wire welder and a gas bottle. Eric of Northfield said, that even I could learn to wire weld! I decided on a 85 amp Century and a tank that is 7 inches in dia. by 2 feet tall. Filled with 75/25 argon/cd. Plus a valve/gauge kit and fire extinguisher all for $488.

So far I have not made one bird nest, but I sure burnt a lot of holes and had to grind off dingleberrys by the hundred! I’ll let you know If I ever get a good weld on sheet metal. With 18ga. and thicker, I’ve had fair results. Anything thinner and I have no finesse!

I installed the frame rails to make an exact perfect wheelbase length on each side. The diagonal distance checks of the suspension mounting points showed I had a 2 inch variation! I tried to spread the short distance (right front to left rear) and I tried moving the right rear of the longer distance toward the left. Nothing!

So I called my brother-in-law Judd and went California trucking for a couple weeks. Somewhere in the desert I remembered a trouble shooting trick. “If you can’t fix it, try making it worse, just to prove you are on the right track!” Then I could hardly wait to try it. “Go Peterbilt”!

Arriving home, with this scheme of creative floor designs, I wedged the body even farther out of shape till it made a loud “BOINK” sound and everything jumped into alignment! I quickly tack welded the floor to the rear cross member and one side rail before it jumped back. I tried to figure out what was happening but finally conceded that it is better to be lucky than smart!

On a 96, the deeper trunk bottom runs almost parallel with ground. The 92 trunk floor runs up hill to the rear and has a trap door for access to the spare tire. I have the donor trunk positioned as a 92. I’m still thinking on the trap door.

The rear engine mount was broken and the power unit was just sitting on the floor of the compartment, it must have made a rude noise transfer into the body! No expansion chamber, just some water pipe with a couple of 90 degree elbows to route it to a straight pipe. Maybe that explains the Porsche Solex carb with an accelerator pump? With my chamber and the accelerator pump working, I would flood the engine quickly!

Brake lines had rotted off but it seemed odd that the front wheel cylinders and the master cylinder only needed to be cleaned. Air compartment of cowl was rotted out on the engine side and to the inside under the dash, but the wiper motor located under there was fine and worked. Go figure!

I could see original green paint under the flaking gray stuff and hand sanded it off the flat areas; that was easy. On vertical surfaces, removing that gray was a bitch! I tried to save what green there was and flat blacked the remaining bare spots.

One of the neighbor kids rode his bike around the 92. Looking over the paint job, he asked, “Is it a army car?”

I said, “Ja, Svenska Acme.”

April 95

92

I said to Ian that this story would never have a ending, but a finish for this article was the 92’s trip to Oconomowoc, Wisconsin, under its own power – all 25 horses, no water pump, no radiator fan, no nonsense, just SAAB!

The engine had good compression right from the start even though one piston ring was stuck. After that “one ride around the block,” I took the exhaust manifold off again to see what the cylinder walls looked like. Really quite good I thought, then I noticed that the stuck ring was now free — amazing!

There are two drain plugs on the transaxle, neither was in a hurry to relieve itself of the black heavy lube. The next day I put in a quart of 10/30 and a quart of diesel fuel for a flush on “the second trip around the block.” The free wheel control on a 92 is a hand lever right on the gear box. Two positions marked “Last” (with a circle over the a) and “Fri,” This car had been sitting for over 25 years and when I tried “Fri,” it amazed me again — the freewheel worked!

Removing the engine/transaxle with a chain hoist came to a sudden halt due to both inner drivers rusted solid to the axles. This was going to be one of those “ya gotta separate the clam shells off of the rubber donuts” kind of a job. The 92 tie rods are attached to the center of the rack (center line of car) and were right in the way. I had noticed the outer rod ends were shot, (a half turn of play in the steering wheel gave me a clue) so removing the rods gave me room to work on the drivers.

When the part number of the tie rod end was put in the computer at my friendly SAAB dealer, we got a blank screen. That didn’t surprise us; 92’s never were sold in the USA, and the first dealers started sales with the 93 model.

So I reverted to the old tried and proven tactic, “a 6 pack in a brown paper bag” placed on the counter of a friendly parts store person on a slow Tuesday afternoon will get you the generic parts book and a chair to sit on! It turns out a 63 Corvette tie rod end fit, but it was too long. Although it was threaded, the rod was also crimped to the original SAAB end, so I just cut off the crimped section of rod to match up with the Vette part.

On other Tuesday afternoons, I learned that the perfect size and shape of the 92 top radiator hose was located on one end of a Buick hose. Also that early VW ignition points would fit (after a little massage with a Dremel tool)!

The points are mounted on the end of the crank. Take off right front wheel, remove wheel well plate, remove point cover, and you may adjust both sets of points! Oh! look under the clutch housing cover if you are wondering where the timing marks are. There are two of them (one for each cylinder) stamped 180 degrees apart on the flywheel.

I got a chance to do really different tasks with this car, like unsticking the solenoids on the “semaphore type” turn signals and simplify their elaborate BOSCH wiring. I made the replica shape arms out of an aluminum license plate. They are not amber plastic nor do they light up. They are bright, light weight, and jump up when you hit the switch.

My dad liked to work with leather, so I had a bit of deja vu when I saw those tie rods moving through laced-up raw hide boots on the inner wheel well. They stop the debris from entering the engine compartment. I found that soaking the boots in 2 stroke oil rejuvenated the old leather. The stop straps for the suicide doors were gone, so I made some from a double loop of my belt. That’s four layers clamped in a vice and sewed with a hand awl one stitch at a time.

The positive cable from “the battery in the trunk” runs a good 12 feet forward to the starter, and all of it needed new insulation. The answer came in a product that was around everywhere in 1950 when this car was new — friction tape!

It took about 3 rolls and about 3 afternoons. I can still smell it!

The fuel tank is located right in the middle of where the trunk lid ain’t! Think about it. After sand blast, flush, and leak repair, the guy at the repair shop said, “paint it with two coats of this and do it outside!” The can had no label and all he would say was, “Bring it back!” I got the sender to work, but I had to go to a 96 gauge. This combo now reads the fuel level backwards! I like it.

“The plywood fire wall,” now there’s a oxymoron! Actually it is a dam to make the air go through the radiator, but it is plywood and not far from the fire. So I remade it out of aluminum and did it in three pieces instead of one.

I could not get Katha to ride with me to the convention. Perhaps she was remembering that first look at the 92. She wanted to follow me in her 900 incase I needed help! That was polite talk for, “No guts!”

The car never over-heated on the 514 mile round trip, averaged 38mpg on fuel, I ran it in the autocross, and on the way home while passing a new Oldsmobile, I saw 104 on the speedometer! OK, so it was in kilometers. It sure felt good!!

The car never over-heated on the 514 mile round trip, averaged 38mpg on fuel, I ran it in the autocross, and on the way home while passing a new Oldsmobile, I saw 104 on the speedometer! OK, so it was in kilometers. It sure felt good!!

“Stroker”